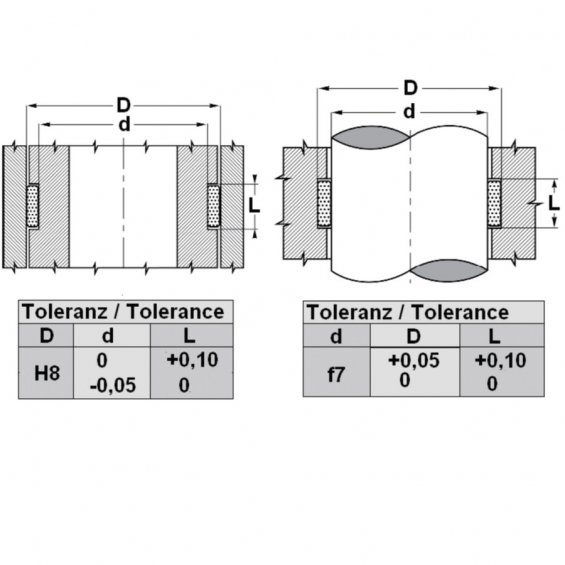

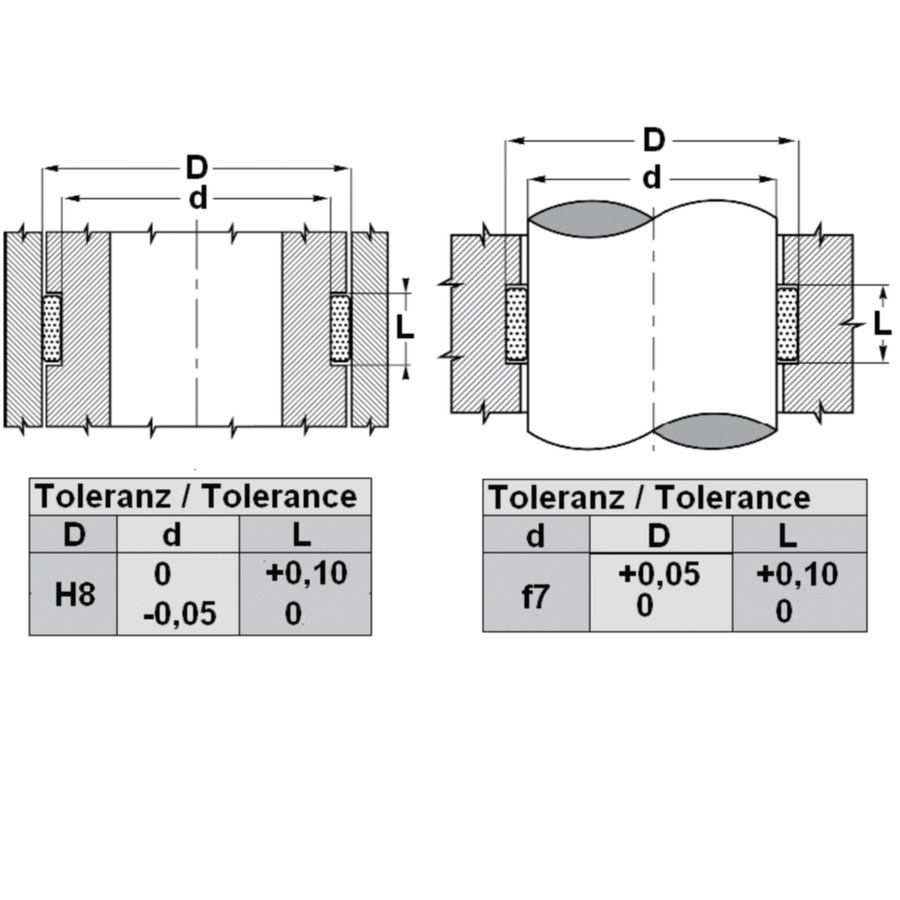

Опис виробу WR 63-1

- d: 63 mm

- D: 68 mm

- D: 68 mm

- L: 9.7 mm

Властивості WR 63-1

- Модель: Двойное направляющее кольцо

- Скорость скольжения макс.: 5 m/s

- Удельное давление: при 20°C 15 Н/мм²; при 100°C 10 Н/мм²

- Температура макс.: 110 °C

- Температура min.: -30 °C

- Рабочие среды: Минеральное масло

- Монтаж: вложить в паз

- Материал: Полиформальдегид + стекловолокно